OHRA stands for quality

OHRA's modern and efficient storage systems are characterised by their outstanding quality, flexibility, and efficiency. The shelving systems are not only robust and durable, but also offer customised solutions for various requirements. The wide range of products, from multi-tier shelving and wide-span shelving systems to innovative storage systems, enables optimum use of the available storage space.

Racks with roof

OHRA presents efficient storage systems with roofs for outdoor storage, which not only extend the storage area but also ensure optimum protection of the shelving system from the weather. Cantilever to pallet racks featuring various roof structures, statically calculated and adapted to regional requirements. These shelving systems are ideal for storing timber, and ensure that the goods are kept dry and ventilated. The advantages include optimum use of space, individual design, installation services including roofing, and a well-balanced price-performance ratio. Weather protection systems such as nets and folding curtains offer additional protection and can be retrofitted. If you have any questions or would like a non-binding offer, OHRA will be happy to provide you with personal advice.

Dynamic shelving systems

Dynamic shelving systems are modular solutions that increase storage capacity and speed up the picking process. Although the initial costs are higher than with traditional shelving systems, the long-term economic benefits can offset the investment. OHRA offers a wide range of dynamic shelving systems, including order picking flow racks and pallet flow racks for heavy loads. Such efficient storage systems cover a variety of applications and budgets. The advantages of OHRA dynamic shelving systems include modular, standardised components, adaptability to the stored goods and area of use, and optimisation of travel distances and picking times.

Pallet flow racks are space-saving solutions that can be installed according to the first-in-first-out principle and enable high space utilisation through passageway formation. Order picking flow racks are particularly suitable for carton goods or crates with roller conveyors and optimise work travel distances and picking times according to the FIFO principle. Push-back racking, also known as trolley systems, are space-saving innovative storage systems according to the last-in-first-out principle and enable the storage of up to 6 pallets deep on trolleys.

Shelving rack

OHRA shelving racks are ideal for storing small parts and non-palletised goods. These galvanized boltless racks are assembled without screw connections and are primarily designed for manual removal of goods. The sturdy shelves have different shelf widths and load capacities and feature several protection edges. The flexibly configurable shelving racks are available in heights of 2,000, 2,500 and 3,000mm, while the shelf depth is optionally 400, 500 or 600mm. The individual shelves can be supplied with load capacities of 150, 250 and 330kg, and the maximum bay load is 1,500kg. These racks are tested in accordance with BGR guidelines and allow the shelves to be adjusted in height in 25mm increments. They are also available as double-sided racks.

Wide-span racks

Wide-span racks differ from shelving racks in that they have larger shelf widths and higher load capacities. These racks use horizontal uprights, which can be fitted with either chipboard or steel panels. Ideal for light, medium-heavy, voluminous, or bulky goods such as wallpaper, foam panels, packaging, or cardboard boxes. OHRA wide-span racks are spacious and strong, with galvanized frames and cross beams. The shelf heights are adjustable in 25mm increments, and the shelf widths are optionally 1,500, 2,000 and 2,500mm with a shelf depth of 500, 600 or 800mm. With shelf heights of 2,000, 2,500 and 3,000mm and a maximum bay load of 2,500kg, these racks offer versatile storage options. The individual shelves can bear loads of up to 500kg and there is a choice of shelves made of chipboard or galvanized steel panels.

Request an individual consultation now!

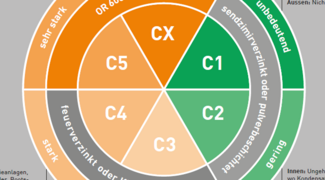

OR6000® corrosion protection

OR 6000® is an innovative coating system from OHRA specially developed for shelving systems that are exposed to extreme environmental conditions. This system offers maximum corrosion protection of storage systems and exceeds the requirements of DIN EN ISO 12944, particularly in the CX category. Even after 6,000 hours of exposure, the coating shows no signs of fatigue. The process includes zinc phosphating, cathodic dip coating (CDC), and up to two layers of powder coating. The fully automated process guarantees outstanding results, a protection of approx. 50 years, and a wide range of applications in various industrial sectors. Further information can be found in the OHRA Download Centre.